Rittal integrates fluid cooling into EPLAN Data Portal

Rittal has added fluid cooling data to the EPLAN Data Portal, thus expanding the previously integrated electrotechnical macros and 3D data for control cabinet engineering with fluid-specific information. Users can now plan cooling systems in an integrated manner with the electric schematics, the fluid power schematics for the cooling technology, and the 3D macros for control cabinet engineering. Aside from accelerating design and engineering, both maintenance and servicing also benefit from more integration as part of this process.

Designing integrated cooling systems

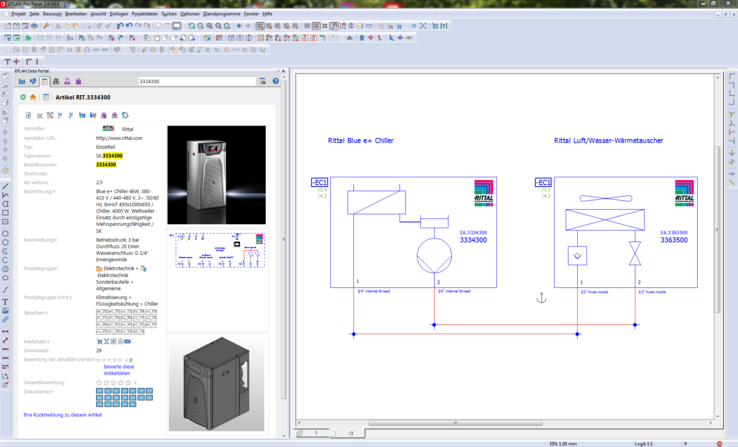

Rittal has added fluid cooling data to the EPLAN Data Portal, thus expanding the previously integrated electrotechnical macros and 3D data for control cabinet engineering with fluid-specific information. Users can now plan cooling systems in an integrated manner with the electric schematics, the fluid power schematics for the cooling technology, and the 3D macros for control cabinet engineering. Aside from accelerating design and engineering, both maintenance and servicing also benefit from more integration as part of this process. Herborn/Monheim, Germany, 28 November 2017 – The synergies between Rittal and EPLAN are enhancing benefits for users of climate control devices and cooling units. Rittal’s device data for fluid cooling currently in the EPLAN Data Portal has now been expanded with the EPLAN discipline “Cooling”. The fluid power schematics thereby profoundly supplement the overall documentation. The result for users is integrated EPLAN engineering for the cooling subsystem, which includes the electrical schematics, the fluid power schematics for the cooling technology and, as needed, 3D macros for control cabinet design with EPLAN Pro Panel. The simplicity of operation is what makes it so persuasive: easy selection criteria such as pressure range, connector dimensions and performance characteristics make choosing the correct devices from within the EPLAN Data Portal easy.

Benefit: Integrated control documentation

There are three specific advantages: Integrated engineering of the fluid cooling (chillers and air/water heat exchangers) in EPLAN with the simple integration of Rittal documentation ensures high design quality and thorough documentation. Along the established value creation chains, for instance in the automotive industry, it results in benefits for all stakeholders in the supply chain. It reduces needed efforts for original equipment manufacturers. Users receive more support in system selection, thus reducing the design time because subcontractor documentation for cooling systems is easy to merge according to the end customer’s standards. And plant operators also benefit, receiving thorough, higher quality documentation since all the relevant control/technical subsections, including the cooling, are part of the fluid power technology brought together in an EPLAN project. Maintenance and servicing are also greatly simplified with this complete documentation.

Two-stage support down the entire line

Even very early on in the design phase of the cooling system, EPLAN users can use the device data and macros from the Rittal Fluid Cooling product area as black-box placeholders. The advantages are clear: important information about connection dimensions for coolant inlets and outlets, plus data for operating pressure, flow range and performance characteristics are already available in this phase of the process, which simplifies choosing the optimal system. With the expanded data, the fluid power and electrotechnical design can be documented in an interdisciplinary manner – either jointly or in separate workflow scenarios by fluid power and electrical engineers. In the second stage – parallel to delivery of the fluid cooling system to the customer – Rittal likewise expands the customer documentation with the fluid/technical specifications. Users can thus integrate the system documentation into the project in just one step using copy-and-paste. The previous placeholders in the fluid technology design are then immediately replaced with the detailed schematics according to EN 1861 and already contain all of the connections to the electrotechnical controls.

More

- <link file:45856 download file>Download Press kit

- <link http: www.rittal.de _blank>www.rittal.de